15 Min To drive smarter production growth with AI in Cabinet Manufacturing

Introduction: The Next Frontier in Cabinet Manufacturing

Imagine a cabinet manufacturing process where machine precision meets human creativity, where production lines are smart enough to optimize themselves in real-time. For many manufacturers, this is not just a dream but a rapidly approaching reality. Embracing AI is not just about adopting new technology—it’s about transforming the very fabric of operations to meet the future with open arms. This is at the core of AI in Cabinet Manufacturing and its growing impact.

Table of Contents

This blog delves into how AI is reshaping the cabinet manufacturing sector and why it’s critical for businesses to harness its potential. By the end, you’ll understand the impact of AI on processes, product quality, and overall business growth, and you’ll be equipped with strategies to implement AI effectively in your operations. For many, this marks the beginning of leveraging AI in Cabinet Manufacturing to scale sustainably.

Understanding the Impact of AI on Manufacturing

AI is a game-changer for any industry, but its potential in manufacturing is particularly potent. By integrating AI, a cabinet manufacturing business can transform different aspects of its operations, including the adoption of AI in Cabinet Manufacturing for workflow optimization.

1. Enhanced Precision and Quality Control

Automated systems powered by AI can oversee the intricacies of manufacturing, ensuring that every product meets stringent quality standards. Machine learning algorithms can detect defects more accurately than the human eye, reduce waste, and ensure consistent quality that sets your brand apart. This commitment to precision is a core advantage of AI in Cabinet Manufacturing.

Case in Point: Precision Cabinets Inc.

Precision Cabinets Inc. implemented AI-driven optical inspection to enhance their quality control checks. This technology detects even the minutest defects during the production process, ensuring that only the best products are sent to market. As a result, they noticed a 30% decrease in product returns and complaints, establishing trust and brand loyalty among their customers. Their story showcases how AI in Cabinet Manufacturing creates measurable, long-term improvements.

2. Predictive Maintenance and Reduced Downtime

AI can predict machine failures before they occur, enabling preemptive action to avoid downtime. This is achieved through constant monitoring and analysis of machine performance data. For businesses, this means fewer production halts and greater uptime—one of the strongest benefits of AI in Cabinet Manufacturing

3. Optimized Supply Chain Management

AI enables businesses to analyze vast datasets to forecast demand, manage inventories smartly, and ensure timely procurement of raw materials. This intelligent automation leads to reduced costs and enhanced customer satisfaction by meeting delivery deadlines consistently. Smart inventory decisions driven by AI in Cabinet Manufacturing strengthen both production and profitability.

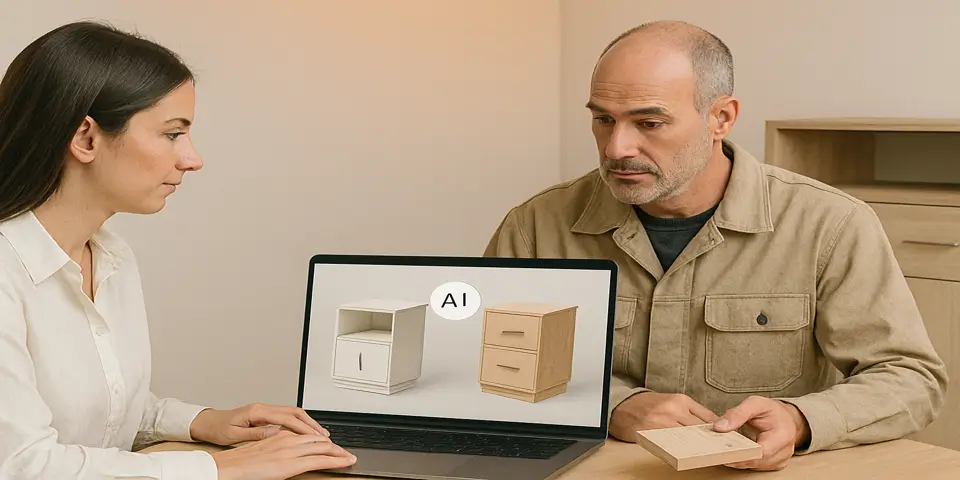

4. Personalized Product Customization

AI’s ability to process large volumes of data translates into offering personalized product recommendations based on consumer preferences and habits. For cabinet manufacturers, this could mean custom designs that cater specifically to individual tastes. This is another dimension where AI in Cabinet Manufacturing enhances consumer appeal.

Leveraging AI for Business Growth: Strategic Approaches

1. Investing in the Right AI Technologies

Identifying and investing in the right AI tools is paramount. Technologies like machine learning, natural language processing, and robotics are shaping the future of manufacturing. Strategic adoption supports long-term implementation of AI in Cabinet Manufacturing.

2. Upskilling Your Workforce

As technology evolves, so should your team. Training employees to work alongside AI technologies ensures smooth integration and increases productivity. Offering workshops and continuous learning opportunities keeps teams updated and confident while maximizing the value of AI in Cabinet Manufacturing

3. Collaborating with Tech Partners

Leveraging expert assistance can accelerate the AI integration process. Businesses can collaborate with tech partners like SySpree, which offer customized solutions tailored to precise manufacturing needs. These partnerships are invaluable for scaling efficiently and effectively with AI in Cabinet Manufacturing.

4. Data-Driven Decision Making

With AI, data is your business’s most valuable asset. Implement data analytics to glean insights regarding customer preferences, production efficiencies, and market trends. This data supports informed decision-making across AI in Cabinet Manufacturing workflows.

5. Fostering a Culture of Innovation

The most successful companies are those that embrace change. Encourage your team to experiment with AI-enabled creative problem-solving. The innovative culture not only leads to unique solutions but also fuels employee engagement and satisfaction. This mindset amplifies the effectiveness of AI in Cabinet Manufacturing in the long run.

Common Obstacles and Mitigation Strategies

Introducing AI into your operations is not without challenges. Many SMEs encounter issues like high initial costs, fears of job displacement, and concerns over data security. Overcoming these is key to a successful transition toward AI in Cabinet Manufacturing

Initial Cost Concerns:

Start small and scale. Implement AI solutions that demonstrate quick results and expand based on proven successes. Many AI tools now offer scalable options perfect for SMEs integrating AI in Cabinet Manufacturing.

Job Concerns:

View AI as augmenting the human workforce, not replacing it. By taking over mundane tasks, AI allows human employees to focus on complex, creative problem-solving roles. This enhances productivity while complementing AI in Cabinet Manufacturing.

Data Security:

Adopt robust cybersecurity measures and ensure compliance with legal standards. Regular audits and updates to security protocols safeguard valuable data and protect all AI in Cabinet Manufacturing systems.

Conclusion: Transform Today to Ensure a Prosperous Tomorrow

AI is proving indispensable in the world of cabinet manufacturing. By enhancing quality, increasing operational efficiency, and powering transformative business strategies, it helps manufacturers excel in increasingly competitive markets. These advancements represent the full power ofAI in Cabinet Manufacturing

Whether you’re just beginning your journey with AI or looking to refine your strategies, now is the time to act. Partnering with an expert like SySpree can provide customized AI solutions to fuel your growth through AI in Cabinet Manufacturing innovation.

Ready to leverage AI for unparalleled success in cabinet manufacturing? Contact us today to learn how SySpree can help you transform your business operations and secure your place as a leader in the industry with powerful AI in Cabinet Manufacturing strategies.

🚀 Want Results Like 500% More Leads in 4 Months?

Let’s talk about what these strategies can do for your business.

👉 Book a Free Strategy Call

We’ll tailor a plan for your goals — no fluff, no pressure.

📧 Or just drop us a line at https://syspree.com/contact/

This is a fascinating deep dive into how AI is transforming cabinet manufacturing. The way you highlight smart design automation, precision optimization, and real-time quality control makes it clear that AI isn’t just a luxury—it’s becoming essential for efficiency, customization, and scalability in furniture production. Looking forward to seeing how this tech continues to disrupt traditional manufacturing.

Your blog is a testament to your dedication to your craft. Your commitment to excellence is evident in every aspect of your writing. Thank you for being such a positive influence in the online community.